Deming PDCA Cycle- Four Stages, Advantages, and Disadvantages. PDSA Cycle Pros and Cons. PDSA or Deming Cycle Revolution. 4 Stages of PDCA.

Deming PDCA Cycle

Deming PDCA cycle refers to a repeated four-step management model that ensures the continuous improvement of products and services in the industry. In the 1950s, a famous management scholar Dr. William Edwards Deming, introduced the PDCA method; therefore, it is also known as the Deming cycle or Deming Wheel. It is a very famous method to solve problems to yield the highest quality result. The full meaning of PDCA is the Plan–Do–Check–Act is a four-step action method.

In addition, it has many names, such as the PDSA abbreviation of the Plan–Do–Check–Adjust, the Deming cycle or circle or wheel, the Shewhart cycle, and the control cycle or circle. The Plan-Do-Study-Act (PDSA) cycle is a quality improvement framework commonly used in various industries, including healthcare, manufacturing, and education.

The Four Stages of the Deming Cycle

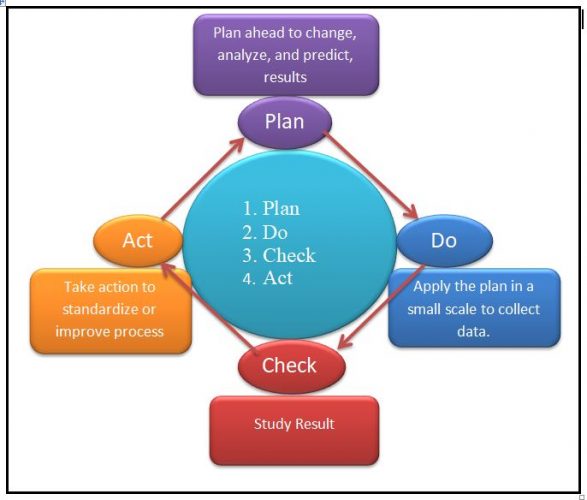

The Four Stages of the Deming Cycle are Plan, Do, Study or Check, and Act. These are the inevitable elements of the Deming cycle.

1. Plan

PLAN is the initial step of the four steps method that identifies the problem and opportunities to suggest recommendations. In addition, it analyzes and describes the overall current situation of the project. The authority recruits a team to understand the full process of the project in this stage; they will identify the problems that need to be changed and find solutions to fix the problems. You have to find out the answers to some basic questions regarding the project. The questions are as follows;

- Firstly, what is the main problem that must need to be solved?

- Secondly, what kind of resources do you have now?

- In addition, what resources do you have to have?

- Moreover, what is the solution that you have taken with resources?

- Finally, how long will it take to analyze the problems and implement the planning?

2. Do

The DO phase is the second stage of the Deming cycle, where the testing of the solution starts to execute to identify the results. After completing the planning step, you have to take action to solve the problems. You will apply all plans that you have taken in the first stage. Some unwanted problems can emerge in this stage, so you have to be aware to confront them. For increasing your confidence level, you can apply your actions to a small arena in the project. It is a subtle way to control the situation properly as well as avoiding an unpredicted big mistake. All team members stay alert at this stage to play their roles and responsibility. In addition, you with your team members will take some initiatives mentioned below:

- Keep a record of what happened and what is happened?

- When do you apply the planning?

- Collect data from the planning stage.

- Try to use a check sheet, swim lane map, and flowchart to capture data.

3. Study or Check

Study or check is probably the most important step of the Deming cycle. You must pay attention to the CHECK stage if you want to scrutinize the output that yielded from the earlier stage. It will help you to avoid repeating mistakes and clarify the success of your planning and applying steps. This stage will allow you to audit your plan’s performance; you will be confirmed whether the plan works perfectly or not. Additionally, your team will identify the problematic portion of the project to eliminate them in the future. You would be able to discover the root cause of the problem if something went wrong. In short, this stage will assess the system’s effectiveness and help you decide whether the theory is helpful or not.

Example: Appraisals or Gap analysis.

- In this stage, you have to answer some questions mentioned below.

- Is the system effective or not?

- Do you want to continue this system or need to change it?

- Have you outlined a list including the unexpected results, failures, successes, and outcomes?

4. Act

ACT is the final stage of the system that finalizes the perfect solution to implement it. In this stage, your organization should follow adapt, adopt, and abandon factors. Adapt refers to changing and modifying the PDSA circle for the next test. Adopt indicates considering expanding the system to all departments in the organization. Abandon means modifying your full approach and repeat the PDCA circle. In sum, it is the step of standardization that is considered standardized when goals are exceeded.

The Pros and Cons of the Deming Cycle or PDSA / PDCA

Firstly, PDSA is a simple and effective process to resolve a new and recurring problem in the industry. In addition, it is a repeated approach that will allow you to measure results without a waste of time. Moreover, it is a risk-free cycle to apply a small scale in the project; therefore, no need to change the full process if it doesn’t work.

In contrast, the full process of the PDSA is slow when applying the four steps in the industry to yield the final result. It is not a straightforward execution process that can apply to urgent problem-solving issues. Additionally, you need to use some resources, including effective team members, to ensure that each circle step is directed perfectly.

The Eight Advantages of PDSA Cycle

- Systematic Approach: The PDSA cycle provides a structured and systematic approach to problem-solving and continuous improvement. By breaking down improvement efforts into manageable steps (Plan, Do, Study, Act), organizations can methodically test and refine solutions to address complex issues.

- Flexibility: The PDSA cycle is flexible and adaptable to a wide range of settings and industries. It can be applied to small-scale projects or larger initiatives, making it suitable for organizations of all sizes and types.

- Iterative Process: The iterative nature of the PDSA cycle allows organizations to make incremental improvements over time. By continually cycling through the steps of the PDSA cycle, organizations can refine their processes, systems, and practices to achieve greater efficiency and effectiveness.

- Focus on Learning: The PDSA cycle emphasizes learning and experimentation as essential components of improvement. By studying the results of each cycle, organizations gain valuable insights into what works and what doesn’t, enabling them to make informed decisions and adjustments.

-

Empowerment of Teams: The PDSA cycle encourages collaboration and engagement among teams involved in improvement efforts. By involving frontline staff in the planning, execution, and evaluation of improvement initiatives, organizations empower employees to take ownership of the process and contribute their expertise and insights.

- Data-Driven Decision-Making: The PDSA cycle relies on data and evidence to drive decision-making. By collecting and analyzing data throughout the improvement process, organizations can identify trends, root causes, and opportunities for improvement, enabling them to make informed decisions and prioritize actions effectively.

- Rapid Implementation: The PDSA cycle enables organizations to implement changes quickly and test their impact in a controlled manner. By breaking down improvement initiatives into small, manageable steps, organizations can avoid delays and minimize the risks associated with large-scale changes.

- Continuous Improvement Culture: The PDSA cycle fosters a culture of continuous improvement within organizations. By encouraging ongoing reflection, learning, and adaptation, organizations can create an environment where innovation and excellence are valued and rewarded.

Disadvantages of PDSA Cycle

While the PDSA cycle offers numerous benefits for continuous improvement, it also has some potential disadvantages:

- Time-consuming: Implementing the PDSA cycle requires time and effort to plan, execute, and evaluate improvement initiatives. For organizations with limited resources or competing priorities, the PDSA cycle may add to the workload and strain resources.

- Complexity: The PDSA cycle involves multiple steps, including planning, implementation, data collection, and analysis. This complexity can be daunting for individuals or teams unfamiliar with quality improvement methodologies, leading to confusion or errors in implementation.

- Risk of Inefficiency: In some cases, organizations may engage in the PDSA cycle without clear goals or objectives, leading to inefficient use of resources. Without proper planning or alignment with strategic priorities, improvement efforts may yield minimal results or fail to address critical issues.

- Resistance to Change: Implementing the PDSA cycle often requires changes to existing processes, workflows, or behaviors. Resistance to change from stakeholders, including employees, management, or customers, can impede the effectiveness of improvement initiatives and hinder progress.

- Limited Scope: The PDSA cycle is best suited for small-scale, incremental improvements rather than large-scale organizational change. For complex or systemic issues requiring comprehensive restructuring or transformation, alternative methodologies may be more appropriate.

- Data Quality Issues: Effective implementation of the PDSA cycle relies on accurate and reliable data for decision-making. However, organizations may encounter challenges with data collection, measurement, or analysis, leading to flawed conclusions or ineffective interventions.

-

Lack of Sustainability: Improvement initiatives resulting from the PDSA cycle may struggle to sustain long-term gains without ongoing support, monitoring, and reinforcement. Without a culture of continuous improvement or organizational commitment, improvements may regress over time.

- Cost: While the PDSA cycle can lead to cost savings through efficiency gains or error reduction, there are also associated costs with implementing quality improvement initiatives. These costs may include training, technology investments, or hiring additional staff to support improvement efforts.

Overall, while the PDSA cycle offers a systematic approach to continuous improvement, organizations must carefully consider its limitations and potential drawbacks to maximize its effectiveness and achieve sustainable results.

The Deming cycle has been evolved from time to time to make it an effective process. I will discuss how the Deming cycle came to be and how it has evolved from time to time.

Dr. W. Edwards Deming

Deming was an American management consultant who graduated as an electrical engineer, later concentrating on mathematical physics. He has become a famous person in the Japanese industry for his work and initiatives after WWII. In addition, Dr. W. Edwards Deming got recognition as one of the most influential Japanese manufacturing industries who are not Japanese but American. He championed the work of Walter Shewhart, including total quality management, statistic process control, and renamed the Shewhart Cycle. After all, He had a great contribution to the rise of the post-war economic growth in Japan.

The Shewhart Cycle

Deming had been inspired by an American engineer Walter Andrew Shewhart who was also a physicist and statistician. In 1939, Shewhart published a book on the Viewpoint of Quality Control. It was the first book that articulated a three-stage systematic process of specification, production, and inspection. These three stages were developed to test the hypothesis of experiments. Finally, he mentioned that these stages should not go straight, but they should go in a cycle. Thus, the Shewhart Cycle came up with the process of a circle.

The Deming Wheel

In 1950, Deming analyzed Shewhart’s Cycle to modify it. He introduced a new version of Shewhart’s Cycle: a four-step of design, production, sales, and research. This cycle has been known as the Deming’s Circle or Deming Wheel.

PDCA

Some Japanese executives probably modify the Deming cycle or Deming wheel into Plan, Do Check, Act (PDCA), although the exact reason for changing the term name is unclear. This four-step cycle was introduced to identify the problems in the industry and solve them by applying four steps together. The prime objective of this cycle is to standardize if the results are satisfying.

PDSA

When to Apply PDSA

The PDSA or PDCA framework can develop any process or product by splitting it into a shorter steps. This cycle can be used in every kind of organization in many aspects such as changing management, new service or product deployment, product lifecycle, and so on. This framework is beneficial for assisting the improvement of the six sigma and total quality management process. It is the best option to dig out problems and practical solutions.

Deming Cycle or PDSA Quality Improvement

The Deming cycle is one of the essential parts of the quality improvement process in the big industry. Apart from that, organizations apply other quality improvements program that is much complex QI processes.

- Continuous Quality Improvement: It is also known as the CQI process that organizations apply to reduce waste, increase efficiency, and increase internal and external satisfaction. It is a management philosophy that assesses how the industry works to develop its process. These more complex quality improvement programs include the following:

- Lean: The lean process is a manufacturing program that effectively improves efficiency and reduces wasteful practices. This program focuses more on improving services and products based on customer’s demands.

- Six Sigma: The six sigma process is the set of tools and techniques that develop the quality of a process by eliminating defects and minimizing variability in manufacturing.

- Total Quality Management: It is a process of a management system based on practicing a principle that instills good business culture where every employee maintains a high standard of work. It influences the organization to maintain a high quality of service in every aspect of the company.

- Quality Improvement Collaboratives: It is a process that usually applies to the healthcare center in which many organizations work together to develop services for patients.

Conclusion

Deming cycle refers to a repeated four-step (PLAN, DO, STUDY, ACT) that ensures the continuous improvement of products and services in the industry. Today, many organizations worldwide use this method to improve the product and service by solving problems.