Red Ocean Strategy and Blue Ocean Strategy Examples & Difference in 2026. Difference Between Blue ocean and Red ocean strategy. Examples of Red Ocean and Blue Ocean Strategy. Also, Blue Ocean Strategy Four Action Framework.

Red Ocean Strategy

Red ocean strategy refers to the traditional marketing strategy to compete with the competitors. It is demonstrated when many companies compete to achieve a competitive advantage in the existing market. These companies contest in the same marketplace to beat their opponents. Red ocean strategy influences the company to provide better service to buyers. It mainly focuses on the existing customers and buyers rather than creating new customers. So, they provide better services and products to attract customers.

Characteristics of Red Ocean Strategy

Firstly, the red ocean strategy focuses on competing in the existing market. So, multiple companies compete with each other to achieve competitive advantages. The marketing team pursues both product cost and differentiation to beat other companies. Additionally, the company intended to provide better service to buyers—finally, they pay more attention to the current customers instead of looking for new clients.

For example, Malaysia and Air Asia Airlines follow the red ocean strategy to beat their competitors like, Air Asia, Batik Air and Thai Airlines.

Red Ocean Strategy Examples

Air Asia is a renowned airline company in Malaysia. It always tries to compete with other airline companies in Malaysia, for example, Firefly, Batik Air, and Malaysia Airlines, to achieve competitive advantages. Air Asia offers low prices on domestic and international flights to beat the competitors. On the other hand, Malaysia Airlines also reduce the price to beat Air Asia. So, they fight each other in the same marketplace. It is a real-life example 0f the Blue Ocean Strategy.

Suppose we infer these giant companies with sharks and the marketplace with the ocean. So, imagine what will happen if all these sharks fight with each other. The ocean gets bloody due to the fierce fight of sharks.

Advantages of Red Ocean Strategy

Firstly, the market has already existed, so no need to create a new marketplace.

Secondly, the services and products have good demand by the customers. Many customers want the products so the new companies can utilize the existing consumers.

Additionally, the company can quickly recruit skilled employees with deep experience in the sector.

Finally, the new companies can get ideas on how to improve the business from their competitors.

Disadvantages of the Red Ocean Strategy

Firstly, competitors are experienced in this market, so it is difficult to beat them.

Secondly, the company needs to focus on cost and differentiation, which is difficult for a new business.

Blue Ocean Strategy

Blue ocean strategy refers to the uncontested marketing policy focusing more on innovation to reinvent the business than the head-to-head competition. W. Chan Kim and Renée Mauborgne introduced the Blue ocean strategy in 2005. It is a simultaneous process of opening a new business market and creating new demand; therefore, competition is irrelevant.

Blue Ocean Strategy Examples

There are several examples of the blue ocean strategy worldwide. Many industries had accepted it to get benefits, such as Netflix, Canon, iTunes, Cemex, Philips, NetJets, Curves, JCDecaux, Quicken, Polo Ralph Lauren, etc. iTunes solved the problem recording industries when it started the business. Before launching iTunes, consumers download a song illegally from the internet platform. ITunes’s blues ocean strategy created a new way of legally selling music, where consumers and artists mutually benefited. They managed to make a new category of music selling through digital music platforms for listeners. Still, it is dominating the marketplace of music platforms for years.

Netflix’s organizational change is the most appropriate example of the Blue Ocean strategy. Netflix changed its business plan to create an uncontested new market. It is one of the most successful companies that accept the blue ocean strategy to achieve competitive advantages.

For example, Netflix, Canon, and iTunes follow the blue ocean strategy to achieve the competitive goal.

Nvidia produces AI chips and sell them that creates an uncontested market. They have made a new market. Therefore, Nvidia is the example company who follows blue ocean strategy.

Blue and Red Ocean Strategy Examples

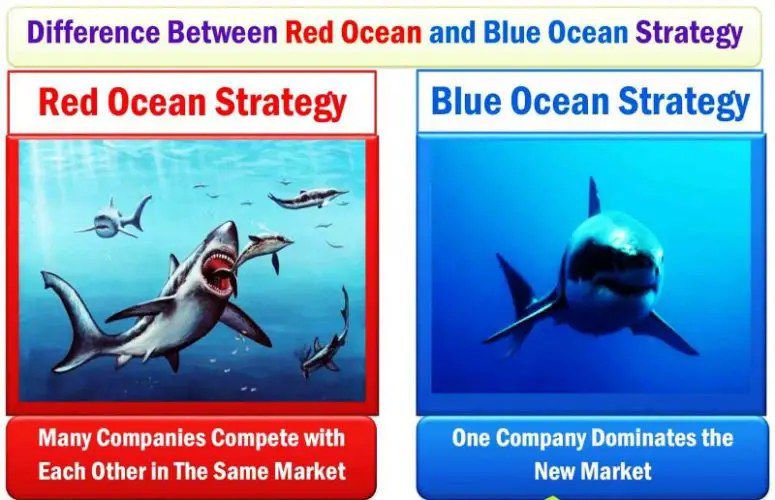

For example, you put some sharks in a pond. Now, they are fighting each other. The sharks are trying to kill others. A few hours later, you can see the water has been red for the shark’s blood. We can infer this pond to the red ocean where many companies are competing with each other.

On the other hand, you put a shark in a separate pond. There is no other shark that can fight, so the water is blue and fresh. We can infer it to the blue ocean strategy where only one company controls the marketplace.

Red Ocean vs. Blue Ocean Strategy

Red Ocean Strategy |

Blue Ocean Strategy |

| The contest is in the same market. | Create an uncontested new market. |

| Many Companies compete with each other in the existing market. | One Company dominates the new Market. |

| Beats competitors. | Competitors are irrelevant. |

| The company pursues both cost and differentiation. | The company chooses between cost and differentiation. |

| Make the value-cost trade-off. | Break the value-cost trade-off. |

| Capture new demand. | Exploit existing demand. |

| Focus on rivals within its industry. | Focus across the alternative industry. |

| Intend to provide better service to buyers. | Redefine the buyer group. |

| Focus on current customers. | Focus on new customers. |

| The market is already established. | Need to make the new market. |

| For example, Ryanair and Air Asia Airlines. | For example, Netflix, Canon, and iTunes. |

Difference Between Red Ocean and Blue Ocean Strategy

1. Focus on Current Customers vs. Focus on New Customers

Most industries focus on attracting existing customers to sell more products and services in the red ocean strategy. Thus, they focus on the current customer to make benefit by selling products and services.

In contrast, in the blue ocean strategy, the industry tries to change the business pattern to yield something new for the customers. The company also broadens the business area to develop new products or services; therefore, customers are irrelevant here. Thus, this strategy allows the company to focus on business patterns rather than customers.

2. Compete in Existing Markets vs. Create New Markets

From the red ocean strategy perspective, the industry is doing business with customers where some industries gain more clients, and some other sectors lose clients. They are doing business with the same customers and competing with each other to get more customers. The company will earn more money if it can bring more customers under its umbrella.

The blue ocean strategy never suggests the company compete because it makes a new uncontested marketplace. The product and service are unique; therefore, no company will come to compete with you. So, this strategy creates an uncontested market to serve its customers.

3. Beat the Competitor vs. Make the Competitor Irrelevant

The competition must exist in the company’s marketplace that follows the red ocean strategy. They compete to sell more products and services to increase profit margins. So, they always intend to beat the competitors through marketing policy, product quality, and services.

The blue ocean strategy makes the competition irrelevant because they need not compete with other industries to sell products and services. It makes a new marketplace for the industry.

Key Points of Blue Ocean Strategy

The eight critical points of the Blue ocean strategy are as follows;

- It’s grounded in data not only assumptions.

- It pursues differentiation and low cost to create new market.

- Blue ocean creates an uncontested market space.

- It empowers you through tools and frameworks.

- Blue Ocean’s strategy provides a step-by-step process.

- It maximizes opportunity while minimizing risks.

- Blue ocean also builds execution into strategy.

- It shows you how to create a win-win outcome.

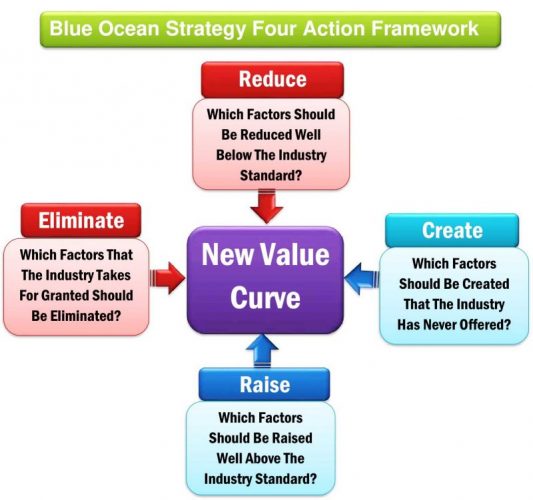

Blue Ocean Strategy Four Action Framework

Chan Kim and Renée Mauborgne developed the four-action framework to destroy the trade-off between low cost and differentiation and rebuild an industry’s strategic logic. The four Actions Template determines whether the investment money is used correctly to maximize consumer gain and minimize consumer pain. It also assesses the gains with this template and the pains that matter for your product. It is the best way to get the most benefit with the lowest price within the total product market.

Four Action Framework Examples

How to Use Four Action Templates

Eliminate

Firstly, you have to identify the factors of the industry that need to be eliminated because of defectiveness. Find out the elements where you give significant investment and effort but get very little output. These factors can also be made more contributions in the past but are now useless, so you need to eliminate them because of becoming obsolete.

Reduce

Secondly, you need to identify factors that are unnecessary for the industry and cannot correctly benefit the industry. These factors are well below the industry’s standard. For example, the higher cost of manufacturing can reduce the product.

Raise

These significant factors need to be increased to fulfill the industries well above standards. For example, the company needs to rebuild the features to exceed the customer’s challenges.

Create

These are the new features that the company never provided. To create these new features, you must investigate the customer’s desire to fulfill them. The industry can also create new products or offer innovative consumer services. It will help the company to create a new marketplace distinguished from the competition.

Conclusion

In short, the Red ocean strategy refers to competing for the existing marketplace, whereas the blue ocean strategy denotes making a new uncontested marketplace. Based on the discussion, it is safe to say that the blue ocean is a better way to bring fewer risks, more success, and increased profits. In addition, the four action templates appear as the best solution to identify the industry’s investment is properly or not. Hence, the blue ocean strategy and the four action framework have become innovative business innovations.