David Berlo’s SMCR Model of Communication Example Situation. Berlo’s Model of Communication Advantages and Disadvantages

David Berlo’s SMCR Model of Communication

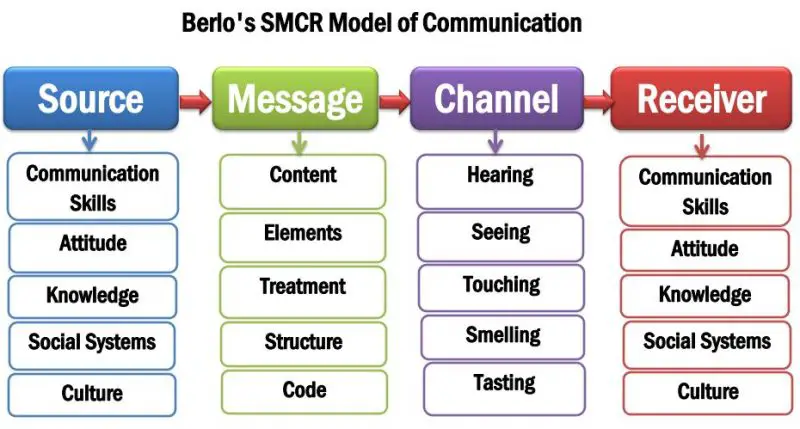

SMCR communication model refers to the Source-Message-Channel-Receiver formed communication theory developed by David Berlo in 1960. In 1960, David Berlo designed the SMCR communication model with four elements: Sender, Message, Channel, and Receiver. SMCR refers to the Source-Message-Channel-Receiver, which are essential elements of any communication process. Therefore, the SMCR communication model is known as Berlo’s Source-Message-Channel-Receiver model. Berlo invented this model based on the Shannon-Weaver communication model (1949). He described some factors that make the communication process more effective. SMRC represents the Source, Message, Channel, and Receiver that are also part of 9 essential communication elements of the primary communication process.

There are three types of communication models: linear, interactive, and transactional communication models. The SMCR communication model refers to the one-way communication system. So, the SMCR model is a linear model of communication where feedback is absent.

Berlo’s Model of Communication Published Year: 1960

Who Developed the SMCR Communication Model?

Answer: David Berlo

SMCR Stands For

SMCR stands for Sender, Message, Channel, and Receiver

Models of Communication

Berlo’s Model of Communication Example

Listening to a lecture in a classroom is a real-life example of David Barlo’s SMCR communication model. Lecturer Delivering a Lesson Physically in a Classroom can be an example situation of Berlo’s model of communication. The four essential elements of Barlo’s model are the source, message, channel, and receiver. Firstly, the news lecturer is the source of knowledge who disseminates the information. The lessons are the message, and hearing and seeing are the channel. Finally, the students are receivers of messages who listen to the lecture. In this context, students can be a source of information when they provide feedback. David Berlo did not mention feedback in his model; therefore, it is designed to explain a one-way communication process.

Similarly, reading newspapers, books and magazines are example scenario of Barlo’s communication model. Print and broadcast journalism primarily relate to one-way communication.

However, digital journalism generates two-way communication, including social media-based citizen journalism and blogging. The active audience can comment to express their opinion on social media sites including Facebook, Instagram, and WhatsApp.

Berlo’s Model of Communication Diagram

David Berlo’s Communication Model Elements

The Four Key Elements of Berlo’s Model of Communication are:

- Source

- Message

- Channel

- Receiver

1. Source

The source means the message’s sender who initiates the communication process by sending information to the Receiver. David Berlo describes five factors related to the source: Communication Skills, Attitude, Knowledge, Social Systems, and Culture.

Communication skills

Communication skills refer to the ability to speak, read, write, and listen effectively. It also indicates the ability to use verbal and nonverbal communication cues during the interaction. Communication will be more effective if the senders and receivers have excellent communication skills. The most common nonverbal communication examples are eye contact, facial expression, body language, gestures, posture, and so more. The communication skill of the source or sender increases the effectiveness of the communication process.

Attitude

Attitude is the psychological factor of the sender and Receiver that affects the message’s meaning. It is also an established perception of a person in which they think or feel about something. Thus, the message’s meaning depends on the source’s attitude and the Receiver.

Knowledge

Knowledge indicates the level of actual information, familiarity, and experience on the discussion topic. The discussion topic is the message of the communication process. Therefore, the communicator feels comfortable discussing if the topic is familiar to them. However, knowledge does not imply the educational qualifications or degrees of the sender or receiver.

For example, a football player will be more interested in talking about football than cricket. On the other hand, a cricket player will surely feel comfortable discussing a cricket game. Here, knowledge indicates familiarity with the subject of the discussion topic or message.

Social Systems

Social systems refer to the values, beliefs, behaviors, rules and regulations, locations, and religions. These factors influence the method of the communication process as well as the meaning of the message.

For example, the speaker delivers an anti-America message in the American parliament election campaign. It is considerably sure that the audience will not receive and listen to his message attentively. It is an example of a location factor that is also part of the social system.

Culture

Culture refers to the social background of the Sender and Receiver. The meaning of the same message might be identical when people from different cultures interpret it. It is a significant factor from the perspective of nonverbal communication cues.

For example, exchanging “Salam” greetings with people is widespread in the Muslim community. Salam conveys a greeting message in the Muslim community; however, handshaking is another activity that also exchanges the same meaning. On the other hand, handshaking is a standard greeting among people in Western culture.

2. Message

The message is the primary substance conveyed by the source or sender of the communication to the Receiver. David Berlo proposed another five factors related to the message: Content, Elements, Treatment, Structure, and Code.

Content

Content refers to the entire body of the message from beginning to end. It is essential information for the discussion. Content is the whole script of the conversation.

For example, the lecturer is teaching students about noise in communication. So, the full speech about communication noise is the content of the message.

Elements

Elements refer to nonverbal communication cues such as facial expression, eye contact, gesture, posture, and body movement. It makes the conversation more effective and productive. So, communication might get boring without elements.

For example, the lecturer raises five fingers when mentioning the five basic noises in the communication process.

Treatment

Treatment refers to the communication way in which the message is conveyed to the audience. The communication way affects the communication system. It represents the message packaging. Examples of treatment in communication are delivering messages formally and casually.

For example, the teachers speak formally when delivering speeches in the classroom. However, the lecturer talks very casually when meeting students outside of class.

Structure

The structure of the message describes the arrangement of the information. The effectiveness of the message depends on the message structure.

For example, the lecturer talks about the definition, types, and examples of communication noise. The students perceive the message clearly for its good arrangement.

Code

Code in the message refers to the form of the message transmitted from sender to receiver. Examples of the code are text, audio, video, visual, and so more.

For example, the teacher is speaking in front of the students; hence, the code of the message is audio.

3. Channel

Channel refers to the medium that carries the message from sender to Receiver. There are many types of channels in communication, such as radio, newspapers, TV, phone calls, and social media. Berlo highlighted the five senses as the communication channel: hearing, seeing, touching, smelling, and tasting. These five channels are a crucial part of the human communication process.

For example, a face-to-face class is more effective than an online class. The students can see the lecturer physically and hear the lecture. Nowadays, many institutes conduct virtual classes through premium. The channels denote the physical and virtual communication way to convey messages.

David Berlo mentions only five human senses as the communication channel, such as Hearing, Seeing, Touching, Smelling, and Tasting.

Hearing

People receive messages through listening. It is the most effective channel in the communication process. For example, students hear lectures in the classroom.

Seeing

People accept messages through seeing. It is one of the crucial channels in nonverbal communication. People take less than one second to judge others by seeing their appearance. The audiences form a conception of the speaker based on body movement, facial expression, eye contact, and gesture. A proverb says that people can lie, but eyes never lie. It means people believe what they see more than what they hear.

For example, a lecturer asks students about their final exam. The student replied that it was an excellent exam; however, the student looked very worried while interacting with the lecturer. So, the lecturer does not believe the statement due to seeing the worried face. Watching television is another example of seeing channels in communication.

Touching

Touch refers to an effective nonverbal communication channel that conveys messages through touching. It is also known as Haptics in Nonverbal Communication. The most common examples of touching channels in communication are holding hands, hugging, tickling, and kissing. These touching styles represent different messages.

Smelling

Smelling is another channel of the intrapersonal communication process. The intrapersonal communication process means communicating with yourself. It is also known as olfactics nonverbal communication. People judge others based on the Fragrance they have used. A good smell creates a positive attitude toward the person. The perspiration odors form a negative perception of the person. A good fragrance represents a good personality.

For example, people smell flowers and fragrances to identify whether the flavor is good or bad.

Tasting

Tasting refers to nonverbal communication channels through tasting something. For example, people test food to identify its deliciousness.

4. Receiver

Finally, R-Receiver is the person who receives the message or information in the communication process. David Berlo adds the same factors of the sources to the Receiver, such as Communication skills, Attitudes, Knowledge, Social Systems, and Culture, to the Receiver. Communication gets more effective when senders and receivers have similar skills, attitudes, and knowledge. Communication among people from the same culture and social system reduces communication noise during the interaction.

Berlo’s Model of Communication Example Situation

(Berlo’s Model of Communication Example Scenarios: A Marketing Officer Selling a New Television)

1. Source (S)

In this scenario, the marketing manager is the source of information who initiates the communication.

- Communication Skills: The marketing manager should be a verbal and non-verbal communicator to convey the message effectively.

- Attitude: The marketing manager needs to have a positive attitude and details information about the new television.

- Knowledge: The sales manager should study the new product and the customer’s demographic and psychographic background.

- Social System: The manager works within the organizational structure and culture.

- Culture: The manager’s approach and style might be influenced by the organizational culture and background of the audience.

2. Message (M)

The promotional information about the new television is the message.

- Content: it is information about the new television, including components, usefulness, pricing, and launch date.

- Elements: Verbal and non-verbal communication cues including artifacts, presentation slides, statistic report charts, and television images.

- Treatment: The way of conveying information including formal presentation with a Q&A session.

- Structure: The whole session includes an executive summary, product features, market analysis, and conclusion.

- Code: The marketing manager uses language in promotional presentations, including technical terms, and possibly visual and audio elements.

3. Channel (C)

In this scenario, hearing and seeing are the channels in which a message is transmitted.

- Hearing: The customers and sales team listen to the manager’s speech about the new television.

- Seeing: The customers see visual aids and observe non-verbal cues.

- Touching: Some audiences touch the new television to know more about it.

- Smelling and Tasting: It does not apply to this product. However, it might be applicable for food items.

4. Receiver (R)

In this scenario, the clients are receivers of the information.

- Communication Skills: The customers and sales team must have good listening and little knowledge about the product.

- Attitude: It indicates the customer’s willingness to buy the new products. It might be positive or negative towards the new television. It is also relevant to psychological noise in communication.

- Knowledge: Similar to the marketing manager, the customers and sales team should have knowledge and positive attitudes toward the new television.

- Social System: The marketing session is designed and operated according to the company’s hierarchical structure and social norms.

- Culture: The customer’s cultural background and corporate culture may influence their perception of the message.

Berlo’s Model of Communication Advantages and Disadvantages

Advantages of Berlo’s SMCR Communication Model

Berlo’s communication model explains the communication system with four primary and 15 sub-components. It shows a giant diagram to describe the communication process thoroughly. The SMCR model explains the communication process elaborately.

The source or sender and receiver contain similar components. This model articulates that the sender and receiver convey and receive messages simultaneously. It indicates interactive communication even though it is a linear communication model.

It focuses on human communication emphasizing the skills, attitudes, knowledge, and social systems of both the sender and receiver.

Disadvantages of the Berlo’s SMCR Communication Model

David Berlo’s SMCR Model of Communication is the linear communication model; therefore, feedback is absent. Hence, the SMCR model can’t explain the transactional communication processes like speaking over a smartphone.

Additionally, it illustrates a complex communication model that is difficult to understand. This model troubles students in perceiving the process.

Moreover, Berlo’s SMCR communication model avoids noise, a significant communication element. It excludes another communication element- context. It is impossible to describe the communication process without noise and context.

Conclusion

SMCR is one of the significant linear communication models that describe the communication process through multiple elements, including Sender, Message, Channel, and Receiver. Although this model mentioned various components, it is a one-way directed. Berlo’s SMCR model is known as the one-step communication model; whereas, the two-step flow of communication is the interactive model. In sum, the SMCR model is also a linear model of communication since feedback is excluded.